Chemicals are classified as non-hazardous or hazardous. In healthcare settings you may come into contact with several different chemical substances, for example cleaning agents, disinfecting and sterilising agents, laboratory chemicals.

In healthcare settings, you may come into contact with several different chemical substances during your work.

These include:

- cleaning agents

- disinfecting and sterilising agents

- laboratory chemicals

- medical gases

- anaesthetic agents

- cytotoxic drugs and pharmaceutical substances

Managing hazardous chemicals

Having a chemical management system helps you manage, handle and use hazardous chemical agents safely.

The system should:

- review all chemicals

- identify hazardous chemicals

- identify and assess the risks

- identify and implement controls

- evaluate and monitor

- consult with staff

Review chemicals in use

Inspect your workplace for the chemicals being used. Look at all activities and processes that produce chemicals.

Chemicals are classified as non-hazardous or hazardous.

Non-hazardous chemicals should be listed on an inventory. They must be stored and used in accordance with the manufacturer’s instructions. They do not need a risk assessment.

Hazardous chemicals must be listed on an inventory and undergo a risk assessment. You must put in place the control measures identified in the risk assessment.

Identify hazardous chemicals

Information about hazards can be found on the container label and the safety data sheet (SDS). This information is required to complete a suitable and sufficient risk assessment.

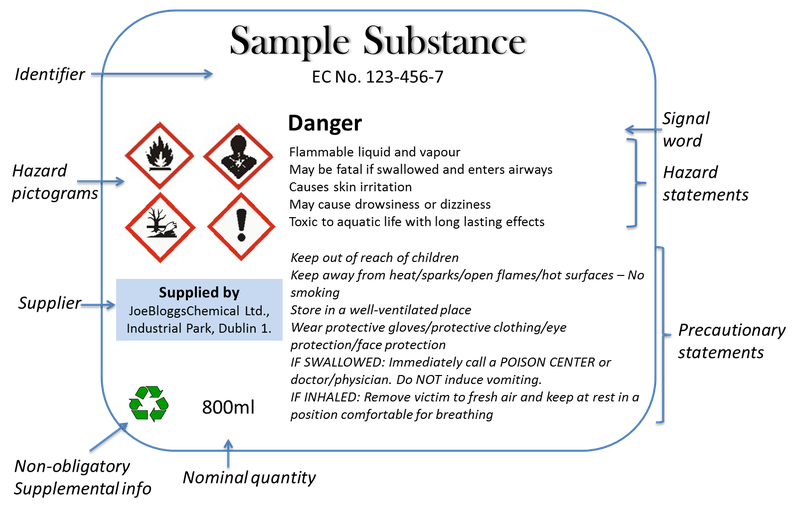

Chemical container labels

The chemical container label shows the name, address and telephone number of the supplier and product identifiers.

Where applicable it shows:

- hazard pictograms

- hazard statements

- precautionary statements

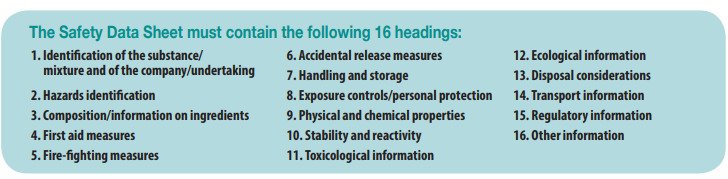

Safety datasheet

An SDS must be provided from the supplier for each chemical and contains 16 headers

For more information see your steps to chemical safety - HSA.ie

See also: Inventory sample

Identify the risk

Once you've identified the chemicals and their hazards, you need to assess potential exposures.

You should review each hazardous chemical and consider:

- who uses the chemical? (for example, how many people use the chemical)

- how long is each user exposed the chemical? (for example, full shift or a few minutes)

- how often is the chemical used?

- how is the chemical used? (for example, sprayed, poured)

- how will the user be exposed? (for example, skin contact, inhalation)

- how much is used?

- can non-users be exposed? (for example, people working near the task, patients, visitors, cleaning or maintenance staff)

Assess the risks

After identifying the chemical hazards and potential exposure, you must assess the risk.

You should review:

- existing control measures

- incidents that have occurred

- audit findings

Assessing the level of risk (risk rating) involves:

- the likelihood that a specified hazardous event may occur or reoccur

- the potential impact of harm or loss to staff, service users, services, environment or the organisation as a result of the event occurring

To determine the risk rating, refer to HSE enterprise risk management policy and procedures 2023 (PDF, 1.4 MB, 76 pages)

Sample risk assessments

Sample bleach chemical agents risk assessment (PDF, 442 KB, 4 pages)

Chemical agents risk assessment sample formalin (Word, 77 KB, 7 pages)

See also:

Guidance on completing chemical agents risk assessment form (PDF, 252 KB, 4 pages)

Chemical agents risk assessment form (Word, 147 KB, 5 pages)

Chemical agents risk assessment fillable form template (Word, 112 KB, 4 pages)

Guidance on completing a cytotoxic drug risk assessment form (PDF, 237 KB, 4 pages)

Cytotoxic drug risk assessment form

Cytotoxic drug risk assessment fillable form template (Word, 72 KB, 4 pages)

Medical gases

Medical gases are used within hospital settings for many purposes.

A medical gas is defined as one that is manufactured, packaged, and intended for administration to a patient in anaesthesia, therapy, or diagnosis.

A chemical agent risk assessment must be completed where there is a risk of occupational exposure to a medical gas during use.

Examples of exposure to a medical gas during use include:

- clinical administration

- connection to medical device

- connection to manifold system

The NHSF have developed a prompt sheet to help support mangers review and update the risk assessments in relation to the safe storage and handling of medical gas cylinders. Risk assessment - safe storage and handling of medical gas cylinders PS 048 00 (PDF, 921 KB, 17 pages)

Occupational exposure limit values (OELVs)

An occupational exposure limit value (OELV) is the maximum concentration of a harmful substance that a person can be exposed to without getting sick or hurt. OELVs are in place for some chemicals. These can be found in the approved code of practice 2024. They should be documented in your chemical inventory.

You should ensure that exposure levels to chemicals that contain OELVs are regularly monitored. This is to ensure that the occupational exposures values are not exceeded.

It is recommended that this monitoring is undertaken by a competent person such as an Occupational Hygienist also known as an Industrial Hygienist.

Occupational hygiene

Managers must complete risk assessments to establish if occupational hygiene monitoring is required. If monitoring is required, engage with an occupational hygienist.

For a list of occupational hygienists, contact the National Health and Safety Helpdesk on 1800 420 420.

Occupational hygienists improve workplace practices by identifying, evaluating and controlling exposure to chemicals and physical agents, for example, noise and dust.

Occupational hygienists usually operate as part of a multi-disciplinary team. This can include managers, safety professionals, occupational health professionals and employees. Occupational hygienists may also be known as industrial hygienists.

You must ensure that exposure to chemicals and physical agents does not exceed the occupational exposure limit.

Repeat monitoring

When an employee’s exposure exceeds the OELV, additional controls to reduce exposure are required. Repeat monitoring is essential to ensure control measures to reduce exposure are effective.

Managers must ensure:

- defined occupational exposure limit values are not exceeded

- monitoring is done on a regular basis, or as prescribed

Occupational Hygiene Monitoring in the Workplace (PDF, 670 KB, 8 pages)

Implement controls

The best way to reduce risks from dangerous substances is by elimination or substitution. This is known as the STOP principle.

Replace the dangerous substance with a safer alternative. For example, using a pellet instead of a powder form of the chemical. This could significantly reduce the level of dust inhaled.

Use physical barriers to reduce risks from chemicals

You can reduce chemical exposure by placing barriers between employees and chemicals. These barriers could be fume cupboards, forced ventilation or a scavenging system.

Work practices that help to reduce risk from chemicals

Where possible, minimise employee exposure to chemicals. Try and identify work practices that may be altered to avoid exposure.

You should:

- reduce the number of employees involved in a task

- restrict access to an area where the chemical is being used

- provide chemical safety training

- store chemicals safely

- put emergency procedures in place

- provide washrooms and adequate waste disposal

- provide health surveillance as appropriate

- put in place a preventative maintenance programme for engineering controls

Personal Protective Equipment when working with chemicals

You should only use Personal Protective Equipment (PPE) when working with chemicals in an emergency. It is not an alternative to other suitable control measures. The PPE should provide adequate protection from the hazardous chemicals throughout the exposure.

Consultation

Other professionals can also help with chemical safety management.

These may include:

- local safety representatives

- safety professionals

- National Health and Safety Function

- occupational health

- occupational hygienist

Occupational health

Occupational health provides health surveillance programmes.

Health surveillance is important for:

- detecting ill-health effects at an early stage

- providing data to help you evaluate health risks

- enabling employees to raise concerns about how work affects their health

- highlighting lapses in workplace control measures

- training employees on health effects and use of protective equipment

Risk assessments should identify the need for health surveillance. Health surveillance will identify if more controls are required.

You should refer employees with symptoms of chemical exposure to Occupational Health.

Reporting risks to the service risk register

You must report risks that cannot be controlled locally to your service's risk register. Risks are reported in line with the integrated risk management policy (PDF, 927 KB, pages)

Related documents

Decontaminating with hydrogen peroxide (SA:009:04) (PDF, 334 KB, 4 pages)

Guidance on completing chemical agents risk assessment form (PDF, 252 KB, 4 pages)

Chemical agents risk assessment form (Word, 147 KB, 5 pages)

Chemical agents risk assessment fillable form template (Word, 112 KB, 4 pages)

Guidance on completion of occupational safety and health risk assessments (PDF, 1 MB, 16 pages)

HSE guideline on the safe handling and use of cytotox drugs

Cytotoxic drugs fast factsheet (PDF, 1 MB, 2 pages)

Cytotoxic drug risk assessment form (Word, 103 KB, 4 pages)

Cytotoxic drug risk assessment fillable form template (Word, 72 KB, 4 pages)

Guidance on completing a cytotoxic drug risk assessment form (Word, 64 KB, 4 pages)

Contact HSE Health and Safety helpdesk (HSE staff only)

Use the Health and Safety Self Service Portal

Phone: 1800 420 420

Monday to Friday 10.30am to 12 noon and 2.00pm to 3.30pm